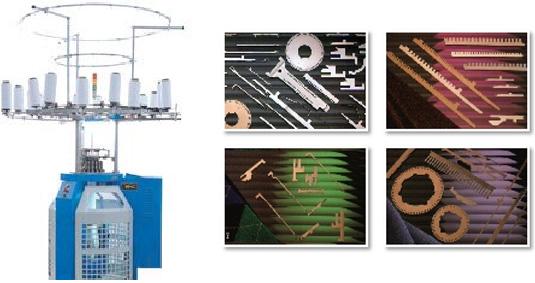

As part of our spares we supply and stock both new and reconditioned sinker bars from 9-33GG using the sinkers and elements of your choice or which ever is more suitable or available depending on the gauge and recently we have even reconditioned sinker bars and supplied knitting elements for 51 & 60gg for the hosiery/stocking industry we believe in today's market we are the only company with enough experience to carry out and supply such high specification components and spares. We are currently the world’s largest supplier of knitting elements of the Mitchell Greive brand. We purchase many of these items in bulk allowing us to offer such elements as sinkers, jacks, points, needles etc for fully fashioned, V bed, circular & sock machines at competitive prices. We offer an exchange service for sinker bars, knock over bars & falling bars using the original polymer material and we also supply all element bars and ancillary parts to change gauges. Excluding where we have found something to be an improvement all parts are made to the original specification by us and in some cases made by the original suppliers to the Monk Cotton International Group.

We specialise and are conversant with all model machines of Bentley-Cotton AE, AEF, E80, F, FT. Monk Superspeed, 2000, 2001 & 2002 and supply the most difficult of parts at competitive prices. We can also offer service and spares for Scheller, Closa and Textima fully-fashioned knitting machines. Alco is also fortuitous enough to be able to call upon the skills of existing Monk and Bentley technicians to help service and rebuild machinery. Our speciality has always been in the supplying of spare parts and service though we do supply used and reconditioned machines. We offer used and reconditioned machines plus a full range of spares for Shima Seiki, Stoll, Exacta, Simet, complett and Bentley, Monk & Scheller fully fashioned cotton machines, along with spares for the machines we support.

RECONDITIONING AND RE-GAUGING

As Monk and Bentley Fully Fashioned Machines are built on solid structures this allows them to be reconditioned and gauge changed many times over.

Due to high costs in machine moving the majority of this work is now undertaken at customer premises and parts are prepared and shipped ready to assemble, however this work can be carried out in our own factory.

The work involves the complete dismantling of the machine, the replacement of all worn bearings, cams, elements and element bars, and all other worn items.

More often than not when we fully recondition machines our customers have a complete overhaul including changing the whole electrical and programming system to a much simplified pneumatic control and AC inverter drive

This modification totally replaces all existing motors, wiring and electro mechanical control systems with simple long lasting pneumatic motors, increasing efficiency and productivity. The new computer controls all the machines functions via pneumatics and AC inverter motors. This is suitable for all types of full fashioned knitting machines Monk, Bentley, Scheller, Textima etc.. and can be fitted in a 2-3 days. In the case of Bentley Cotton machines it totally eliminates the top disk control mechanism and all its components.

This replaces previous systems such as the original Bentley kite system and in some cases where fitted on full width system, this completely eliminates constant changing of straps, chains, belts and expensive hooks etc.

It is supplied in kit form and would generally take 1 day to fit

This completely replaces the old complex conveyor and bar feed mechanisms by a simple, reliable and maintenance free rib loading system, which also ensures a regular control of each individual knitting head by the operator.

2-3-4 colour striping striping can be fitted to all Monk and Bentley Cotton fully fashioned machines and enhance the machines capabilities.

This device can eliminate all snappers, and in some cases other yarn tensions by controlling the pull back yarn at the selvedge with compressed air.

The quality of selvedge is improved, and the maintenance is minimal. The air flow can be set to either actuate in relevant times of the knitting cycle or can be on constantly.

This is a maintenance-free replacement of the AE gear bowl using an improved version of the S.A. Monk rack and pinion type system which is lubricated from the existing automatic oiling system. We can also supply original overhauled gear boxes.

We also sell new motors and in most cases can repair customers servo motors especially those used on the Monk Cotton 2001-2002 model machines.

Alco can also offer new electrical boards for Bentley Cotton, Monk and Scheller machines of which we carry various types in our stock, we also offer a repair service for many types of boards including Indramat panels for Scheller NCI – NCC machines . We also supply electrical boards and motors for various types of flat bed machines, Shima, Stoll, Protti, Universal and more.

We can offer a vast array of elements which include sliders, needles, sinkers, sinker bluffs, selectors, verge bits and jacks, for many brands of sock machines such like LONATI,SANGIACOMO,MATEC, CONTI, NAGATA, UNIPLET, RUMI, COLOSSO, WILDT MELLOR BROMLEY MODEL E, BENTLEY KOMET and terry instruments for the Bentley Komet machines.

We also manufacture and repair needle and element bars for Raschel machines, we have done this for the medical trade for production of bandages etc.